World-Class Provider of Engineered Solutions

At Creative Foam, we understand the value of innovation. Our history spans over 5 decades of exceeding the needs of our customers by exercising care throughout the process. From the initial design phase where we collect all necessary information (environment, specification, performance), your part begins to take shape. We utilize In-House state-of-the-art 3D CAD design software to virtually shape ideas into parts. From this we manufacture a tangible prototype to ensure your innovation comes to life. We have On-Site testing labs which are capable of verifying acoustic and physical properties, as well as a variety of other performance properties. Our focus is always on delivering a complete solution enriched with quality throughout and a seamless process we control internally from the initial design and prototyping all the way to production and shipping.

-

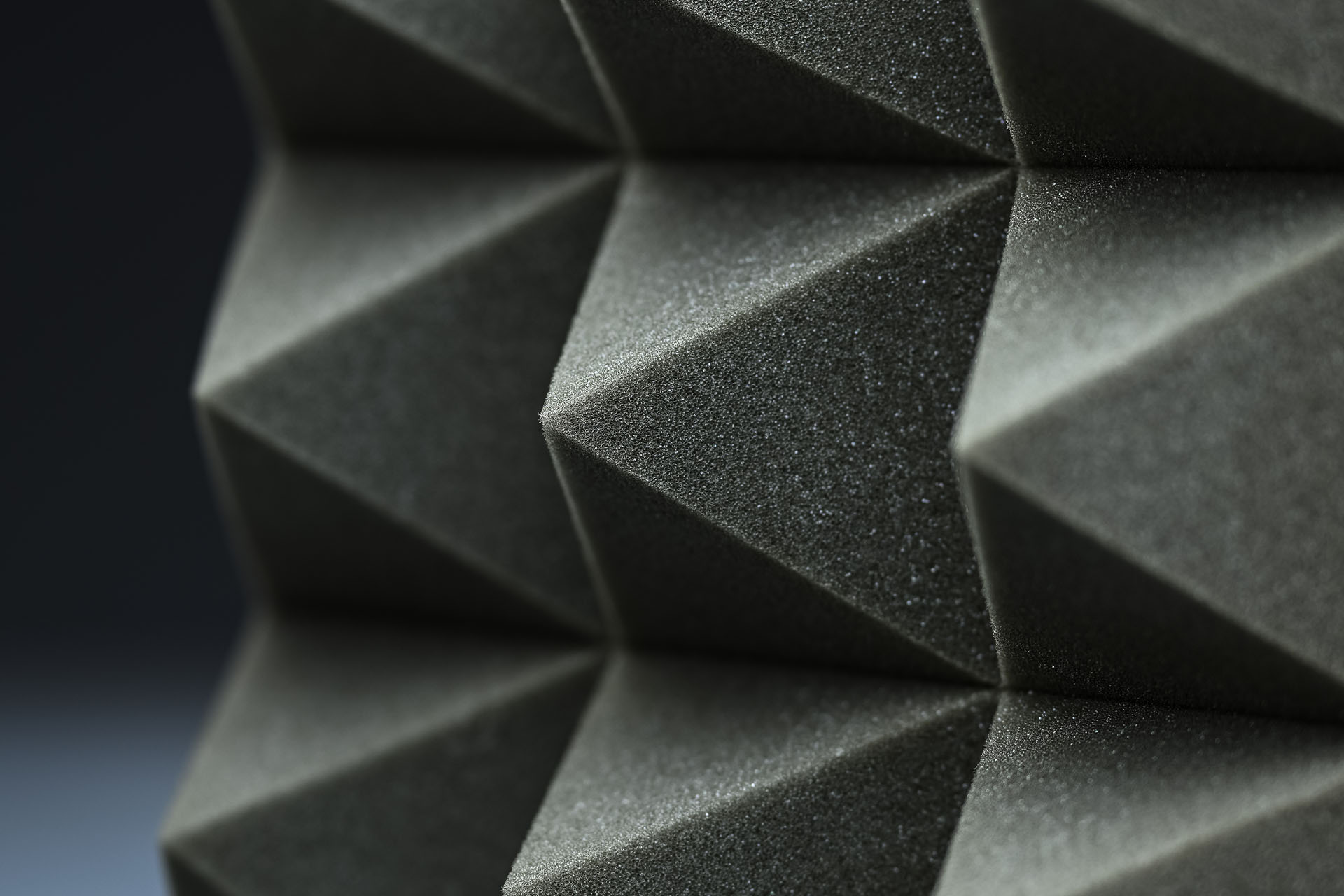

Molded Urethane

Produced in a closed mold or open pour process, we have multiple formulations ranging in density to generate parts that meet your specific requirements. Typical applications range from acoustic seals with intricate shape in dry or wet areas to acoustic mass-decoupler systems in combination with a molded barrier to interior trim parts incorporating a durable in-mold coating.

-

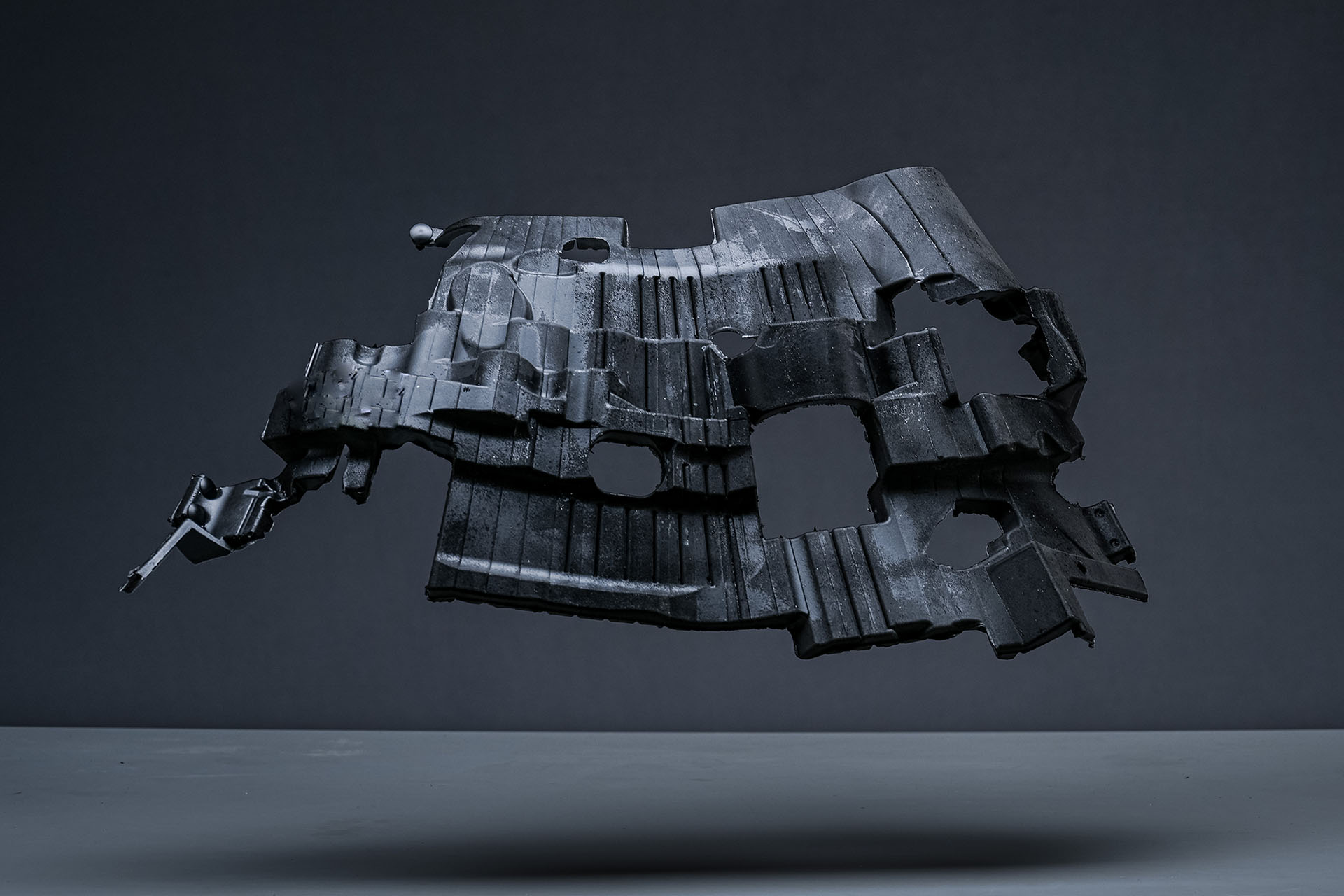

Compression Molding

Compression molding is a thermoforming process that shapes material in a cavity between a top and bottom tool. Tools can be chilled or heated depending on the type of material to be molded. There are plenty of considerations when compression molding as each material has a certain processing window with multiple variables. We are Compression Molding experts and will work with you to develop the most robust and high-quality solutions for your needs.

-

Fusion Molding

Our fusion molding process produces 3D parts by “fusing” multiple foam details together in closed tools. This process yields lightweight closed-cell parts that have the added benefit of being able to incorporate fasteners to the part or create hinges during the fusion process.

-

Vacuum Forming

Our advanced Vacuum Forming operations provide a reliable method for quick production of deep draw parts with complex shapes from impermeable material while ensuring uniform thickness with consistent quality and performance standards.

-

Die Cutting

Our Die Cut Manufacturing operation provides a highly efficient process for mass production of simple or complex components with minimal material waste. With an unlimited offering of solutions ranging from small precision parts produced on rotary equipment to large parts with multiple cavity tools on high tonnage presses, we can handle the tolerances required by the most tightly controlled parts and provide the cost savings associated with multiple cavity tools on our larger presses.

-

Lamination

Our Lamination process typically involves bonding different layers of foam or composite materials together using adhesives and/or heat. Our unbiased offering of materials and lamination techniques enables us to create advanced materials that offer superior properties in impact resistance, thermal insulation, and structural integrity that adhere to your specific requirements.

-

Coatings

Coating operations involve applying a thin layer of material onto the surface of foam or composite components. The choice of coating material depends on the intended purpose, such as providing protection against specific environmental factors or enhancing specific properties of the material. Our advanced coating operations enhance the performance, longevity, aesthetics, and functionality of our products by improving the resistance to wear and tear, extending the lifespan of products, and ensuring the safety and well-being of end-users in transportation, healthcare, and industrial settings. Our coating operations offer a variety of solutions ranging from:

- Resistance to abrasion, chemicals, UV rays and weather conditions in automotive, marine and aerospace components

- Safety in specialized functionalities like Anti-Microbial and Hydrophobic coatings for hospital mattresses, medical devices, and medical equipment

- Protection of industrial equipment from corrosive materials

-

RF and Ultrasonic Welding

Radio Frequency (RF) Welding utilizes electromagnetic energy to create strong and seamless bonds between various materials while Ultrasonic Welding employs High-Frequency mechanical vibrations to produce molecular connections between materials.We utilize our advanced RF weld and Ultrasonic Weld capabilities to offer significant advantages in terms of precision, cost-effectiveness, and increased productivity, making them valuable manufacturing choices for a variety of applications and markets from medical device to transportation.

-

Cut And Sew

Our Cut and Sew processes involve assembling and fabricating materials to create products that meet your specific requirements and performance standards with a high level of precision, quality control, and compliance to deliver functional products that improve the safety, comfort, and efficiency in various applications across the Transportation, Healthcare, and Industrial markets.

-

Clean Room Manufacturing

Our specialized Class 8 clean room facility ensures a controlled environment with low levels of particulate and microbial contamination, providing an optimal setting for manufacturing sensitive and high-precision products. By adhering to strict protocols for environmental controls and cleanliness standards our operations can deliver high-quality, reliable, and contaminant free products for a variety of applications.

-

CNC Contour Cutting

Our CNC solutions offer versatile and efficient manufacturing processes including Saw Cutting, 3 and 5 Axis Machining, Contour Cutting, and Water-Jetting to shape and fabricate materials with precision. Incorporating these diverse CNC cutting techniques allows us to meet all of your production requirements, from simple straight cuts to intricate, multi-dimensional designs.